Strength and Precision: The Role of Metalwork in Modern Construction

Metalwork is more than just a structural necessity, it’s a craft that blends strength, precision, and design. From the steel frameworks that hold up buildings to the decorative finishes that define a project’s aesthetic, metalwork remains one of the most vital elements shaping the built environment today.

Metals like steel and aluminium continue to dominate the construction landscape for their strength, flexibility, and long-term performance. One would say it is the Foundation of Strength. While steel provides the core structural integrity needed for large-scale projects, aluminium offers a lightweight yet durable solution, resistant to corrosion and perfectly suited for external applications.

With advancements in custom metal fabrication, architects and engineers now have the freedom to design structures that are not only functional but visually striking. Bespoke metalwork allows for unique architectural expressions like curved beams, slimline frames, and detailed finishes — that once seemed impossible through traditional construction methods.

Behind every metal structure lies craftsmanship, the unseen precision of cutting, welding, and finishing that transforms raw materials into reliable architectural components. Skilled fabricators understand that even the smallest imperfection can compromise a structure’s integrity. It’s this attention to detail that gives each canopy or shelter its long-term durability and refined appearance.

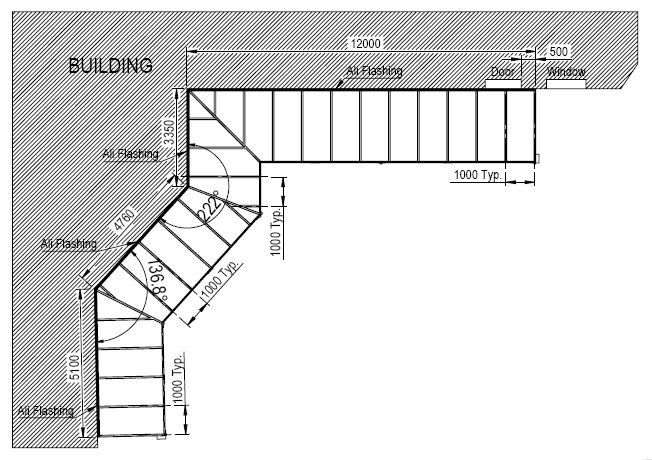

The strength of any structure begins long before the first weld, it starts with collaboration. At Able Canopies, our design and installation teams work closely with architects, contractors, and site surveyors to ensure each structure performs as intended within its environment.

A good example of this collaboration is seen in our anti-ligature assessments, where safety is a top priority. Before installation, our process includes a pre-commencement site meeting and a full risk assessment to review factors such as fixings, water management, and potential concealment of downpipes.

By design, most of our structures naturally reduce the risk of ligature points, but careful product selection and site evaluation remain key to enhancing safety, particularly in sensitive environments such as healthcare or education settings. This is where design precision meets human responsibility.

At Able Canopies, metalwork plays a central role in every shelter we design and manufacture. Each canopy and shelter is engineered using precision-cut aluminium or steel components, ensuring structural integrity, weather resistance, and long-term reliability. Beyond strength, our metalwork allows for flexibility in design. Whether it’s sleek architectural lines for a school entrance canopy or a heavy-duty frame for public walkways.

Every weld, joint, and bracket contributes to a structure that’s built to last, embodying the balance between engineering precision, craftsmanship, and collaboration.

As sustainability and design innovation continue to shape construction, metalwork remains at the heart of progress therefore allowing for recyclable, durable, and adaptable solutions across every sector.

Able Canopies Ltd. design, manufacture and install commercial grade canopies, shade sails, awnings and shelters across the UK. We specialise in servicing the education, leisure, healthcare and retail sectors and have extensive experience working with architects and contracting firms on small and large projects.

For more information or to find out how to submit a tender please contact us

Follow us on our social media accounts for the latest funding advice, new products & latest news:

Twitter | Facebook | LinkedIn | Instagram

Categories

- 20 Years of Able Canopies

- Canopies for Architects & Contractors

- Canopies for Healthcare

- Canopies for Restaurants, Bars and Hotels

- Canopies for Retail & Commercial

- Canopies for Schools

- Canopies for Sports & Leisure

- Canopy Maintenance

- Case Studies

- Cool Links & Facts

- Cycle Parking Solutions

- Dates for Your Diary

- Eco-Friendly Holiday Crafts

- Employee Spotlight

- Environmental Tips

- Funding and Fundraising

- How to... Get the Most out of Your Canopy

- Insights: Able Canopies News

- Latest News

- Latest Stories

- Lockdown Outdoor Learning & Play Ideas

- MD News

- Newsletters - Architects & Contractors

- Newsletters - Schools & EYFS

- Outdoor Learning

- Outdoor Play

- Planning Your Cycle Parking

- Product Focus

- Solar Carports

- Spring Fundraisers 2017

- Summer Shade

- The Good Canopy Guide

- Uncategorised

- Wall Mounted Canopies